The working principle of the SLOFEC® technique

The SLOFEC® inspection system is based on the eddy current principle with superimposed DC field magnetization. With this system objects with up to 25 mm wall thickness and coating up to 10 mm are testable, depending on the scanner type.

The task of the inspection system is to detect defects in tank floors, walls and roofs as well as in pipe walls. Due to the phase spread between subsurface (outside), surface (inside) and other indications the SLOFEC™ Operator is able to distinguish them from each other. Objects with non-conductive and non-magnetic coating, like rubber or paint, are also testable. A special coupling medium is not necessary.

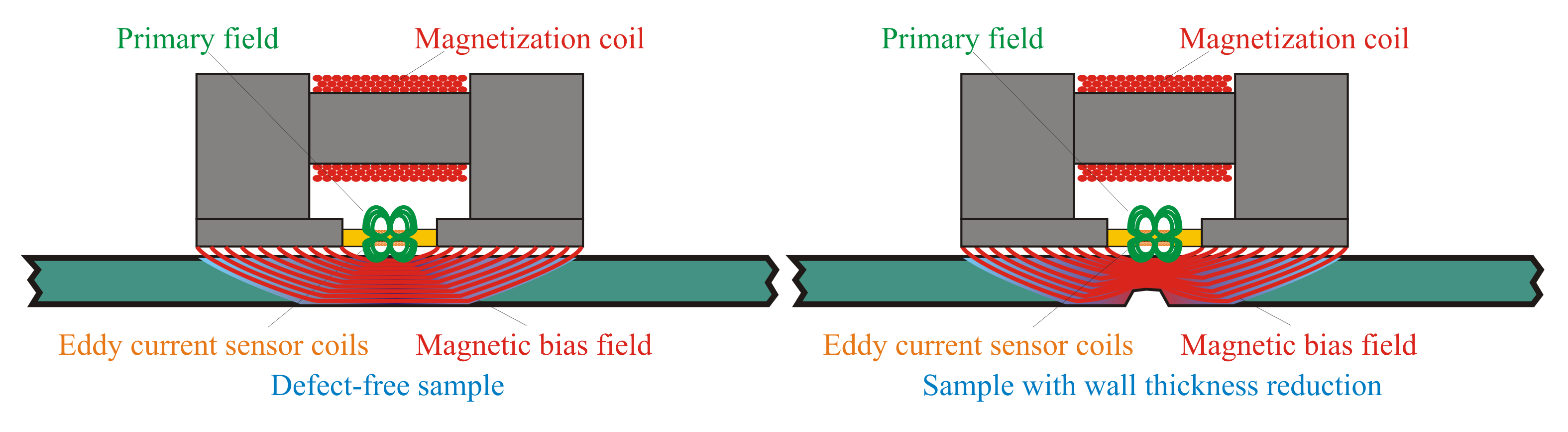

The figure schematically shows the working principle of the SLOFEC® technique. A magnetic yoke containing a permanent or electro-magnet is used to generate a strong magnetic field in the material to be tested. The magnetic DC field has an effect to the material properties of the test sample.

Between the poles of the yoke an eddy current sensor array is located. These sensors also generate a small alternating magnetic field in the material under test, super-imposed to the magnetic bias field of the yoke. The eddy current field is sensitive to changes of the material properties of the test sample. In a defect-free sample the magnetic bias field and therefore the material properties do not change. As a result the eddy current signal is unchanged.

A reduction of the wall thickness, e.g. by a corrosion pit will result in a concentration of the magnetic fields in the remaining wall and resulting in an increased magnetic field strength above and around the defect. This results in a Change of the material properties at this location. This local change of the material properties will be detected by the eddy current sensor.

The eddy current signal amplitude of the defect indication is a measure for the volume of metal loss.